We pioneer. You lead.

Latest news

At the forefront of Industry 4.0

A pioneer of Industry 4.0, we have been offering intelligent and connected solutions that set new standards in the automated cutting of airbags, fabric and leather since 2007. Combining software, equipment, services and data, our state-of-the-art solutions provide a passport to Industry 4.0.

From fashion PLM software to furniture design software, we are combining software, equipment and services.

Latest publications

Customer voice

Experience it firsthand

Book a demo with one of our fashion software specialists

Discover our events

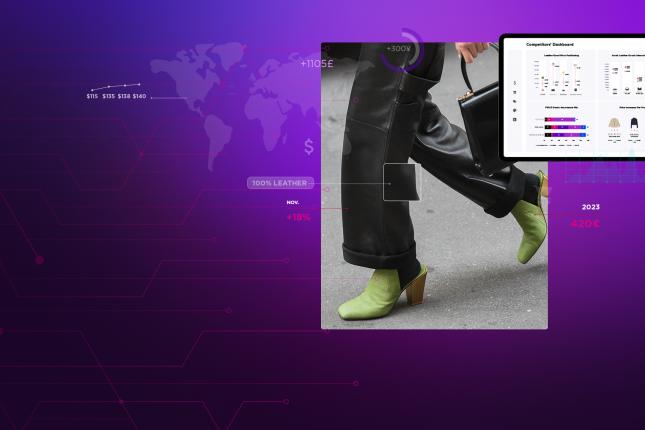

Fashion

Fashion

Follow us on LinkedIn to stay up-to-date on Lectra news