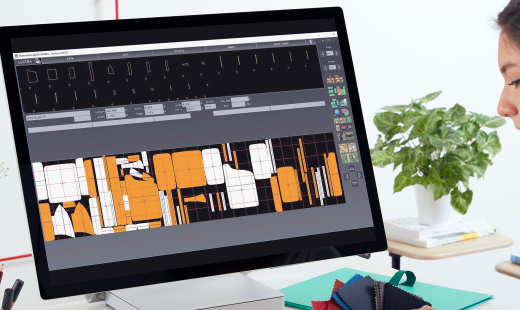

Lectra integrated cutting room offer is a pioneering combination of marker-making, pattern-making, spreading and cutting solutions to enable furniture manufacturers to control costs, minimize waste and shorten production cycles.

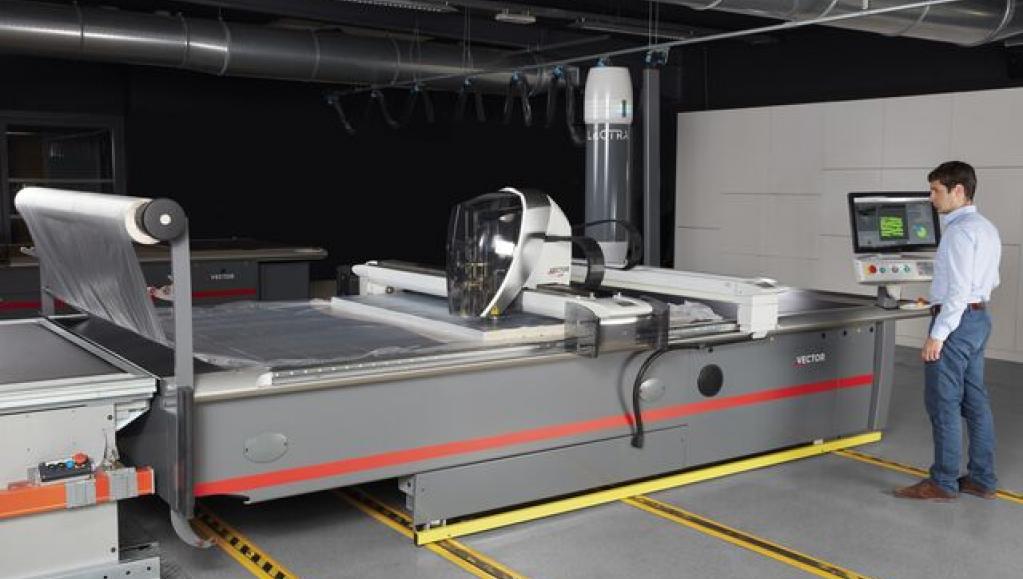

Vector fabric cutting room combines lean-oriented production processes with maximum uptime to deliver improved speed and better-quality products at the lowest cost per cut.

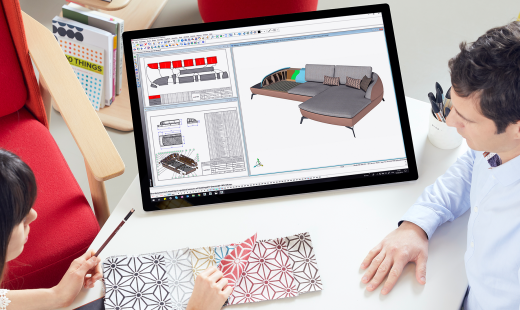

The launch of Furniture on Demand enriched by Valia marks the solution’s compatibility with best-selling fabric-cutting equipment range Vector for the first time ever.

Designed to meet every production need, Vector delivers unprecedented uptime, improved speed, long-term reliability, and optimized efficiency and quality, backed by Lectra’s unique technical and customer support capabilities.