From hide digitization to offloading, Lectra’s Versalis all-in-one cutting solution brings value, speed and precision to your leather cutting room. Whatever your production type, process organization and the leather you use, the complete Versalis range will help you increase material efficiency while being sustainable, deliver consistent quality and cope with skilled labor shortages.

What is Versalis?

Versalis Range

Versalis® XHS Online Mono-Conveyor Scanner

- Single-head Versalis 1HS is perfect for cutting large correctedleather parts at a steady pace

- Dual-head Versalis 2HS offers additional maneuverability to cut medium and small corrected leather parts

Versalis® XHD Online Multi-Conveyor Integrated Digit

- Single-head Versalis 1HD is designed for cutting large corrected- and natural-leather parts at an expedited rate

- Dual-head Versalis 2HD combines faster guidance and optimized cutting movement for medium corrected- and natural-leather parts

Versalis® XHO Offline Multi-Conveyor Independent Digit

- Single-head Versalis 1HO with nesting station and digitizer separates tasks to optimize the processing of large corrected and natural-leather cut parts

- Dual-head Versalis 2HO with separate nesting and digitizing stations accelerates the complete process for large corrected- and natural-leather cut parts

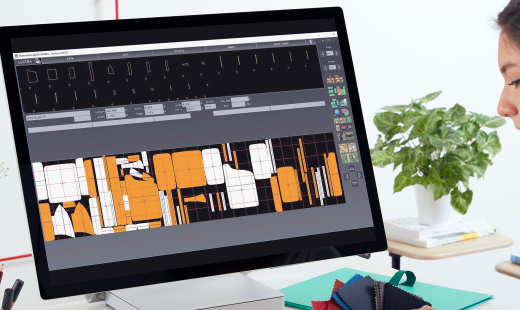

Versalis LeatherSuite

Versalis and LeatherSuite combine to form the most advanced digital leather cutting solution powered by data intelligence. LeatherSuite offers enriched data for process optimization and streamlined execution, enabling manufacturers to achieve performance objectives and monitor production output.

Customer voice

Benefits of 4.0-ready digital leather-cutting line

Cutting productivity of up to 20 hides per hour

- All-in-one cutting line, from hide digitalization to offloading

- Digitally-driven production flow

- Software monitoring for process optimization

- Hide to cut parts traceability to be more environmentally sustainable

Increased hide savings by up to 10%

- Automatic nesting increases material savings by up to 10% compared to a manual process

- Leather consumption analyzed and updated in real time

- Prioritize parts, optional parts cutting and order mixing

- 0 mm between cut parts

Improved and standardized quality

- High-precision, automated leather cutting of even the most intricate furniture shapes

- Great capability and repeatability reaching the highest industry standard

- Up to 5 defect qualification grades recognized by the scanning system

- Automatic optimization of cutting head path

Accurate hide analysis

- All flaw coding levels and grain structure used in upholstery sector

- All hide sizes scanned entirely in one pass

- Scanner / Digitizer precision of +/- 0.5 mm

- Augmented Reality assistance to ease defects detection, nesting and offloading

Increased data-based visibility

- Seamless connection and integration with several ERP, MES, CAD and other systems

- More than 200 embedded sensors for real time reporting, analysis and predictive maintenance

- Smart service technology

- Remote support

Get the latest Versalis resources

Capitalize on expertise to unleash productivity and profitability in leather furniture production

Working with a leather-cutting solution provider with leather expertise may seem like a nice-to-have. Read on to find out why it's actually a must-have.

Efficient? Measure your cutting room

The pressure is on. Speed and costs that need to be constantly reduced and an ultra connected consumer who isn’t willing to wait, yet expects customization and more options than ever before

Success factors for industry 4.0 cutting room

Industry 4.0 has the potential to revolutionize the cutting rooms of furniture manufacturers. Those that get the transition right can benefit from increased efficiency, lower costs and improved accuracy.

Need expert advice about Lectra and our solutions ?

Don't hesitate to contact us

Related solutions

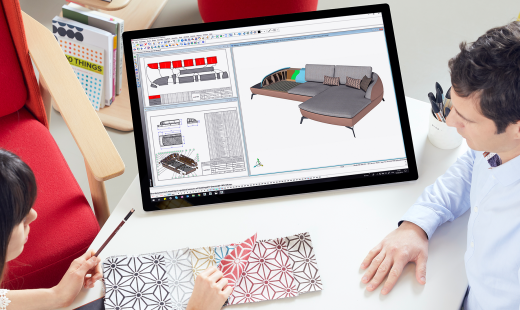

DesignConcept

DesignConcept transforms the way you create, develop, cost and prepare for production. With DesignConcept 3D you can identify the best designs to optimize margins while reacting quickly to demand. DesignConcept 2D then helps you prepare for production with automatically generated technical documentation and pattern fine-tuning.

Formaris and Diamino

Formaris lets you quickly develop pattern pieces and production configurations, taking into account specific trim cover and upholstery constraints, whether using fabric or leather. Then, when it comes to marker making, Diamino uses advanced algorithms to generate complicated markers quickly and minimize fabric waste.

Vector

Vector fabric cutting room combines lean-oriented production processes with maximum uptime to deliver high-quality products at a lower cost. Together with Brio and Mosaic, it provides the agility you need —with automated spreading, precise patterned fabric matching, and high-speed cutting—to handle all high-ply cutting jobs with ease.

Product brochure

Your guide to

Versalis