Manufacturers are under increasing pressure to not only give customers more choice, but to also get their products to market faster. Just look at the fashion industry. Once upon a time, there were a few seasonal collections a year to choose from. Today, there's new stock on the rails every few weeks. Now, the upholstered furniture market is heading in the same direction.

Consumers want complex customization, mix ‘n’ match modularity, designer collections – and more. But they want it all with “express delivery”– not a 12-week wait. How can you deliver faster, while protecting your profits?

Quick Fact: A physical prototype costs 3 to 5 times the final cost of a finished product. Plus, each new model requires anything from 3 to 8 prototypes.From Initial Sketch to a short run of products for retailers to display, each stage is a chance to save valuable time, effort & cost without compromising on quality.If you want to achieve continuous improvement and long-term growth, you need to follow in the footsteps of your customers – you need to evolve.

Here are five tips to help you tackle your time-to-market challenges :

1. Think holistically

Improvement relies on three factors: people, processes and technology. If any of these are a ‘weak link’, it will impact your efficiency and slow you down. The key is to think about them holistically. For instance, if you introduce a new piece of software, plan how you’ll adapt your processes and train your people to make sure you’re achieving maximum return on investment.

2. Minimize prototyping

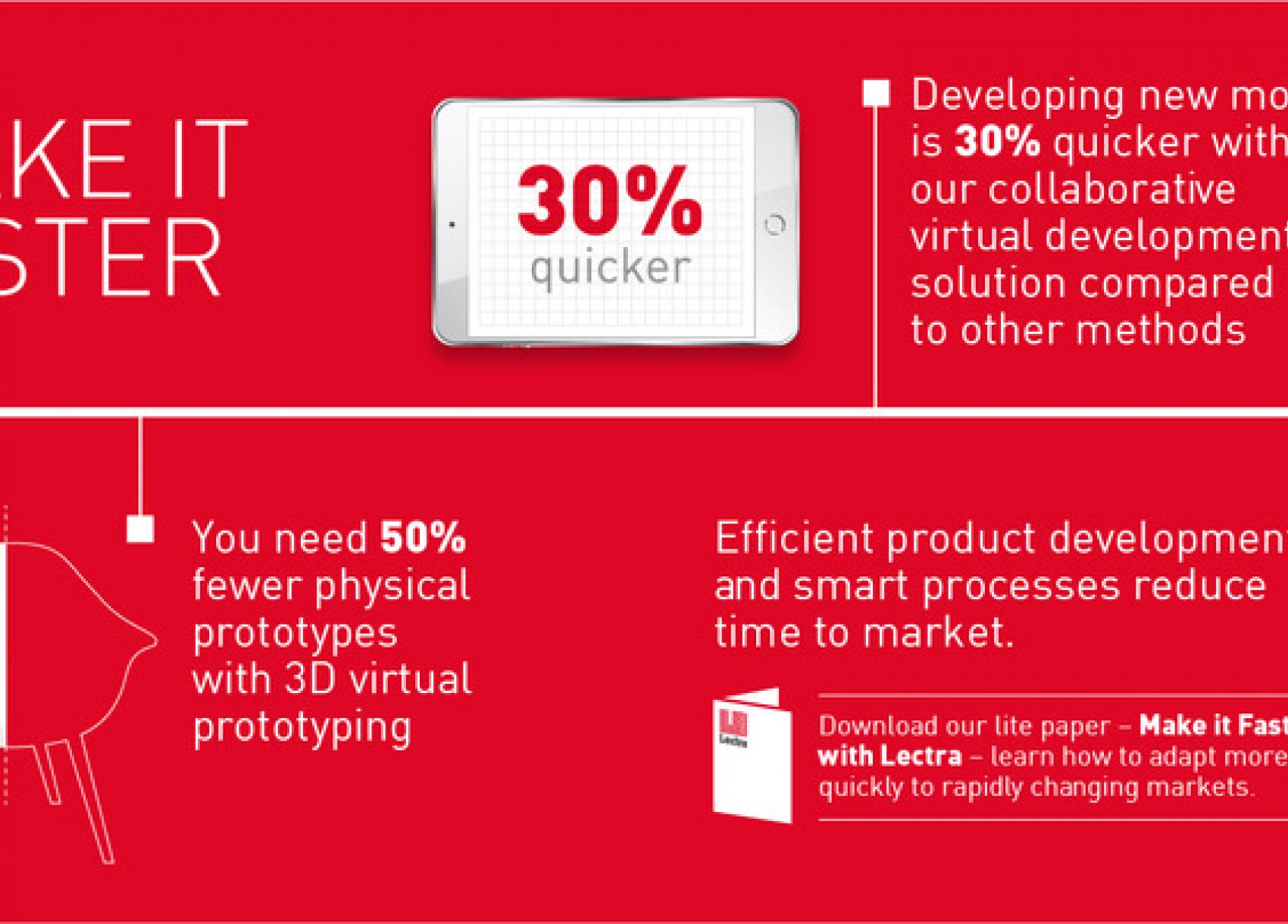

New furniture models typically require anything from three to eight prototypes. That’s costly and time-consuming. With the latest 3D design software and virtual prototyping solutions however, everybody in your entire production chain can have a clearer picture of designs and their costs at an early stage – without the need for physical prototypes. You can make modifications quickly, share them easily and get approvals, faster.

3. Streamline processes

The fewer hurdles there are between your design, industrialization and production processes – the faster you can go to market. With the right software in place, that’s now easier than ever. Rather than making multiple, time-consuming manual updates, you can automatically feed data changes made at the design and prototyping phases (in 3D) into the industrialization phase (in 2D), without losing accuracy. That includes changes to fabric, leather, wood, foam, stitching and so on.

4. Control quality

Quality can create hold-ups at every stage of production. So, the better you manage quality, the less likely you are to have problems. The Six Sigma improvement model can help. It identifies and removes the causes of defects and variability in manufacturing processes. An experienced Six Sigma consultant will be able to look at your current processes and help you plan the right improvements.

5. Collaborate better

By bringing internal teams closer together, you can empower them to collaborate better and increase efficiency at every stage of the validation process. You can minimize errors and speed-up manufacturing time. Don’t forget about retailers either – in order to understand and react quickly to market trends, you need to work closely with them.

What now?

There’s no such thing as a ‘quick fix’ when it comes to upholstered furniture manufacturing. Improvement requires investment, understanding, education and, of course, the right expertise to guide you through it all. But, rest assured, it all pays off.