For firms specialized in aeronautics, wind energy and other fields, personalization, new materials and regulations are just a few of the current market issues they need to handle.

Your market

Industry challenges

To remain competitive, you need to:

Shorten development time

In an increasingly complex and fast-moving industry, development cycles must be simplified by prototyping in more agile and efficient ways.

Increase throughput

Optimizing processes from design to production is vital to keep productivity and profits high.

Optimize material use

Working with costly materials means you need to eliminate waste and error.

Why Lectra?

Lectra helps companies in aviation and aeronautics, wind energy and other industries achieve efficiencies across the entire design, pre-production, and composite and technical textile cutting operations. From 2D and 3D virtual prototyping, to pattern preparation, nesting, and digital cutting, Lectra supports every stage of the design, pre-production and material cutting cycle.

Contact

Fill out the form below and we will contact you soon

Related content

Our areas of expertise

Design to Pre-production

DesignConcept TechTex is a complete 3D/2D CAD solution specifically for the industrial fabric sector. It uses digital modeling to enable fast, detailed product development. With DesignConcept, you can also carry out technical feasibility studies for accurate, immediate material stress analysis and pattern-flattening adjustments.

Leather Cutting

Powered by data intelligence and advanced cut preparation software, Versalis digital leather-cutting solution uses laser projection and hide scanning to ensure cut consistency and efficient pattern placement, reducing over-cuts. Able to cut with no space between pieces, Versalis ensures a maximum of material savings without compromising on quality.

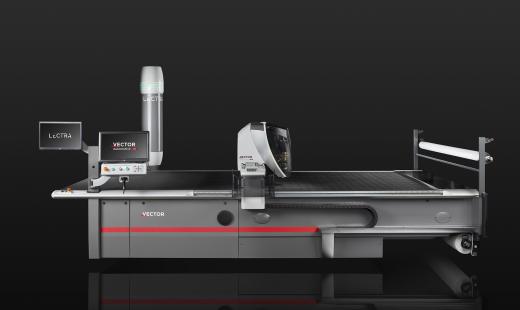

Technical textile and composite cutting

Vector TechTex provides a powerful, intelligent response to the needs of industrial manufacturers. Specially designed for manufacturers using composites and technical textiles, Vector TechTex cutting solution combines fast, high quality cutting with automatic labeling, guaranteeing traceability.