This new consumer behavior is shortening trend cycles, inciting many companies to produce collections based on forecasting and guesswork. As a result, many are struggling to keep up. They are facing issues such as decreased profit margins, high inventory levels, and extreme markdowns due to missed trend opportunities and are working with too many suppliers.

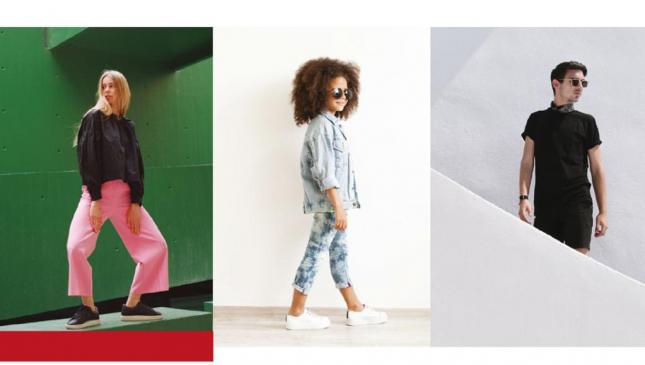

Many companies are now rethinking their approach and seeking to cultivate a deeper understanding of consumer data to provide more personalized customer experiences and better products. This has paved the way for new consumer-centric business models to thrive. Digital native vertical brands are conscious now disrupting the market with products that sell a unique purpose or service.