Versalis Automotive

Industry 4.0 leather-cutting solution

Industry 4.0 leather-cutting solution

Increase flexibility and productivity while also establishing a pathway to Industry 4.0 processes with the Versalis Automotive range.

Want to get the most from every hide?

Versalis Automotive's precise hide quality analysis and pinpoint-accurate cutting empower manufacturers to enhance existing processes, minimize waste, handle increasing complexity, and manage fluctuating production batches.

Boost agility and productivity

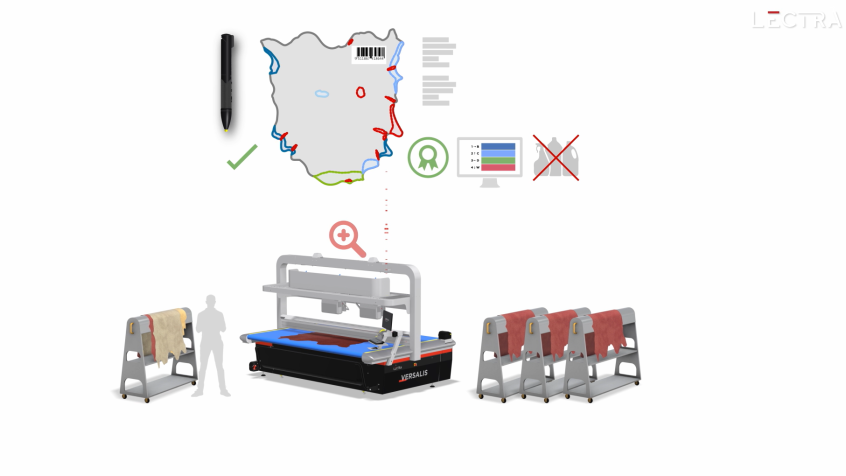

Use a digitally driven production flow, from hide marking to offloading, to simplify processes, improve quality, reduce waste and support sustainability initiatives.

Achieve flawless cut part quality

Produce perfectly cut leather parts independently of the hide type or leather grade. Reduce human error and variability in the cutting room.

Maximize material savings

Reduce operational costs by optimizing material use and obtaining more cut parts from each hide. Increase hide efficiency by 7% with an automated process, compared to a die press.

Get more with Versalis Automotive

Transform your production and preparation methods using digitalization and data. Gather and analyze performance data for rapid decision-making in real-time.

Video file

Enhance process agility

Implement process automation for greater agility in production to reduce costs and better preserve premium leather quality with precise, non-destructive digital marking.

Optimize your processes with data

Harness the power of data to enable smarter, faster, continuous assessment and analysis of cutting room performance.

Control costs and inventory

Simplify quality control of incoming hides using automated grading for improved cost control and improved allocation of hides.

Achieve operational excellence and boost competitiveness

Lower production costs and shorten lead times with improved nesting efficiency to cut more parts using fewer hides.

Create an attractive work environment

Achieve labor retention goals by using innovative solutions and creating a more attractive working environment. Ergonomic design of the cutting station increases operator comfort and safety.

What our customers say

Lode Garmyn

Business manager, ECA

Once we switched from die cutters to the first Lectra solution, we saw an improvement of 10%.

Alberto Silvagni

Head of Gruppo Mastrotto’s automotive business unit

In a business partner, we look for expertise. We look for market leaders that can help us achieve our ambitions in terms of growth.

Lele Ogliaro

Director, Mario Levi

If we hadn’t integrated Versalis into our processes, we probably wouldn’t be as strong as we are today or have the same market penetration.

The Versalis Automotive cutting room

A Versalis Automotive cutting room is more than just a cutting solution. Advanced software and best-in-class services ensure that customers meet their performance objectives.

Versalis Automotive Digital Marking

Versalis Automotive Digital Marking couples a digital marking station with automatic hide repositioning for improved marking accuracy and efficiency.

Versalis LeatherSuite

Powered by data intelligence, LeatherSuite, in association with Versalis, offers enriched data for process optimization and streamlined execution, enabling manufacturers to monitor production output and achieve performance objectives.

5 Benefits of Versalis Digital Marking

Experience the future of marking with digital technology. Simplify workflows, ensure superior accuracy, and unlock savings while enhancing agility and productivity.