Measure what matters most in your cutting room

Real-time KPIs give automotive suppliers the visibility to act fast, reduce waste, and improve efficiency. Download the guide to learn the six metrics that matter most.

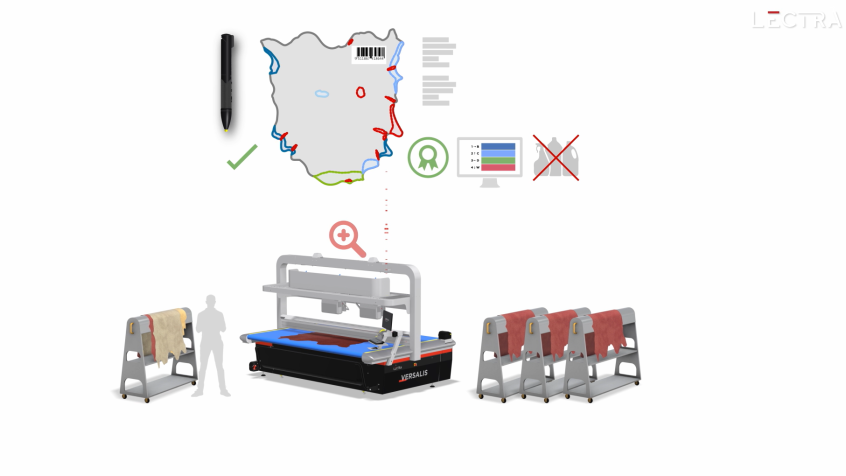

A new reality for automotive interiors

Automotive interior suppliers face a new reality. Development cycles that once spanned years now happen in months. Margins are tighter. Global competition is accelerating. New market entrants are raising expectations and pushing timelines to the limit.

In this environment, cutting room performance is critical to protecting profitability and meeting delivery commitments. Real-time data is the engine that can drive your cutting room forward. With accurate insights driving every decision, you can adapt quickly to changing regulations, fluctuating demand, and evolving customer requirements, without sacrificing speed or precision.

Why real-time monitoring matters

When visibility is limited, inefficiencies remain hidden. Idle machines, unplanned interruptions, and material waste accumulate silently, weakening profitability and delaying deliveries. Without up-to-date data, decisions become reactive and improvement relies on assumptions rather than facts.

Organizations that adopt real-time, digitalized production monitoring achieve faster decision-making, higher productivity, and consistent quality. It helps manufacturers achieve tangible improvements in material use, downtime reduction, and overall productivity. These gains strengthen competitiveness and support sustainability objectives.

Benefits you can measure

Our new eguide, “Measure what matters: Real-Time KPIs that accelerate production and improve cost control” details the six essential metrics for cutting room optimization. It provides a practical framework to help manufacturers improve efficiency, reduce waste, and maintain performance standards.

The e-guide not only explains which KPIs to track but also introduces the advanced technologies that help manufacturers measure performance and act on insights to drive continuous improvement.

By tracking the KPIs detailed in the guide, companies can achieve:

- Higher machine utilization for maximum throughput

- Reduced material waste for stronger margins and sustainability

- Consistent performance across sites for global standardization

- Faster decision-making powered by real-time insights

Latest resources