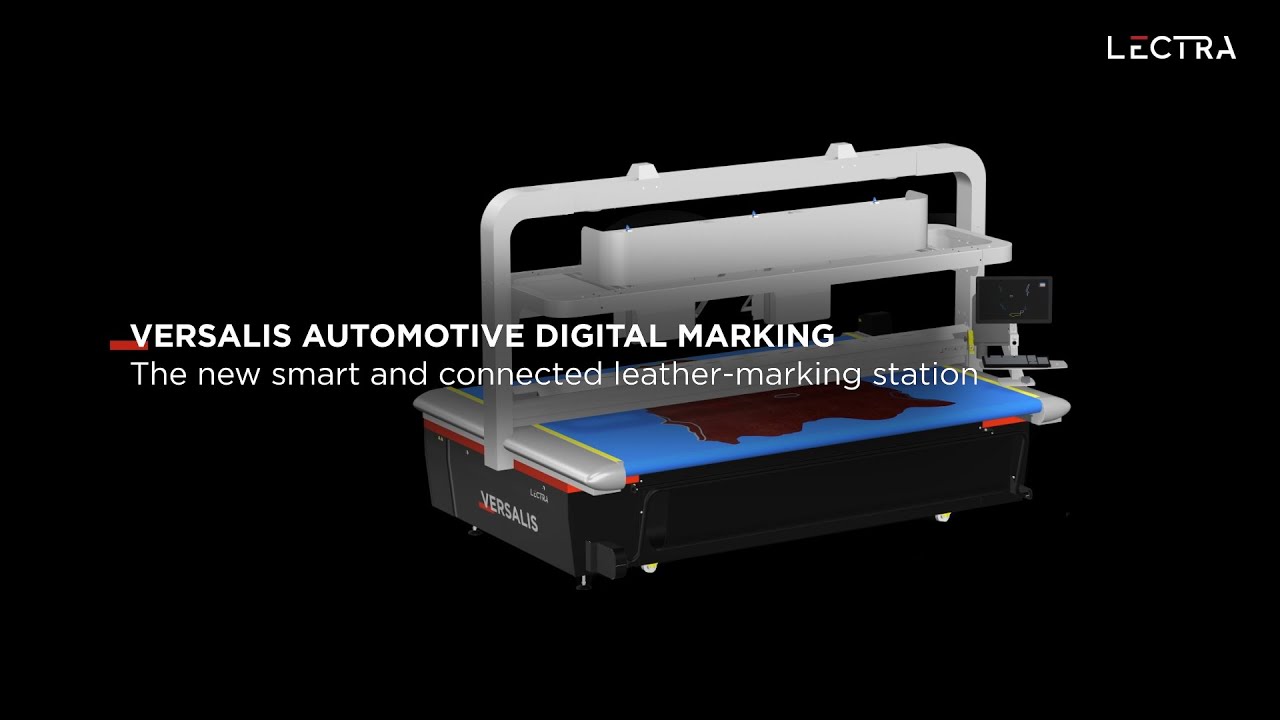

Versalis Digital Marking: Smart, connected leather marking

Replace chalk marking with digital defect mapping and data‑driven nesting. Gain higher yield, faster throughput, and full traceability across your leather cutting process.

Watch the video now and discover how Versalis Digital Marking can transform your leather cutting operations—boosting efficiency, reducing costs, and accelerating time-to-market.

Why leather cutting needs a smarter approach

Delivering interior components that meet stringent OEM standards requires processes that combine precision, consistency, and efficiency.

Traditional leather cutting methods, especially manual marking and nesting, create inefficiencies that slow production and compromise quality. Labor-intensive tasks like marking and replacing die presses often lead to bottlenecks, higher costs, and limited traceability.

Digital technology offers a smarter way forward—automating key steps, improving material utilization, and reducing waste while supporting sustainability goals.

Barriers to efficiency in leather processing

Labor-intensive, inconsistent processes

Manual chalk marking is slow and highly dependent on operator skill. It introduces variability in quality and increases the risk of damaging premium hides. Skilled labor shortages only amplify these challenges, making it harder to meet tight deadlines.

Waste from inefficient hide utilization

Without precise defect mapping and optimized nesting, manufacturers struggle to maximize usable hide surface. This leads to unnecessary waste and higher costs per part. Over time, these inefficiencies erode margins and make it harder to stay competitive.

Limited traceability and visibility

Without a data-driven approach, tracking hide quality and supplier performance becomes extremely difficult. This lack of transparency results in inconsistent standards, costly rework, and missed opportunities for process optimization.

How Versalis Digital Marking helps you

Why should you choose Versalis Digital Marking?

Optimized hide use

Versalis Digital Marking scans each hide upon arrival, enabling creation of a digital twin that includes information such as usable surface area and quality metrics. Hide quality is matched to part type, ensuring optimal use.Reduced rejection of parts

Precise, non-destructive digital marking replaces chalk, eliminating marks that could lead to rejection of cut-parts.Increased cutting precision

Automated hide repositioning ensures perfect alignment—even on irregular hides—for flawless accuracy and repeatability.Controlled costs

Advanced algorithms optimize nesting and reduce scrap, delivering significant material savings and predictable budgets.- Empowered workforce

By automating defect marking and grading, Versalis frees operators from repetitive manual tasks. This reduces fatigue, improves consistency, and allows teams to focus on higher-value activities, boosting overall productivity

What makes Versalis Digital Marking different?

- Increases hide efficiency by up to 1.5%

- Automated hide repositioning

- Digital defect mapping for precise hide scanning

- Real-time data on hide quality and operator performance

- Cloud-enabled monitoring for transparency and traceability

- Advanced nesting algorithms for maximum material yield

Versalis Automotive

Related content