Hongyuan Group chooses Vector Automotive iP to further enhance production capabilities

Hongyuan Group reaffirms its commitment to continuous improvement by once again integrating Vector iP into its processes. This strategic collaboration enables it to consistantly innovate and maintain their position as an industry leader.

Hongyuan Group: A pioneer in China’s automotive industry

Founded in 1994 by Mr. Tsai Tianlai, Hongyuan Group is a trailblazer in the design and manufacturing of violin-shaped car seat covers. Based in Guangzhou, this company was the first manufacturer in China to specialize in this field. Today, with seven production bases and a leather manufacturing plant, Hongyuan Group employs 3,000 people and offers a diverse portfolio of products organized into three key categories:

- Automotive interior products

- Electronic device coverings

- Automotive materials

A mission of excellence

In a highly-consolidated Chinese market, Hongyuan Group emphasizes continuous improvements in its production process. The company has invested in automation to achieve passenger equipment of exceptional quality. With cutting-edge production technology and a strong emphasis on performance and marketing, Hongyuan Group is recognized as a model of excellence in services.

That is why they continue to trust Lectra equipment since 2005.

Lectra enables higher multi-ply cutting and offers greater cutting precision, ensuring we meet our customers’ quality expectations. For example, if you choose another brand’s cutting equipment to process a workload of 7,000 units, you would require 1.5 machines to reach that operational rate. With Lectra, one machine is sufficient.

Jianxin Li, General Manager, Hongyuan Group

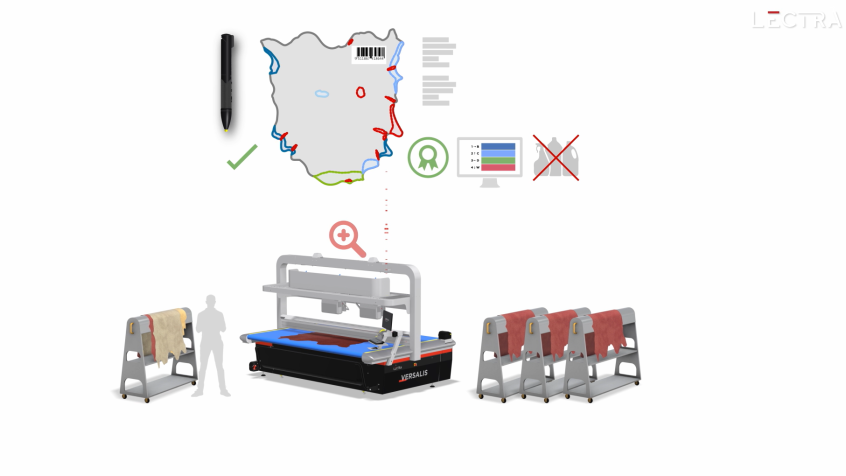

Investing in Vector Automotive iP for greater efficiency

Since its inception, Hongyuan Group has been able to adapt its production capacity to meet the growing needs of its clients. With the installation of new high-end equipment, the company has increased its installed capacity to five units, recently adding two units of iX6 and iP6 models. This advanced equipment enables higher extraction rates and greater cutting precision, meeting customers' quality requirements.

Innovation does not stop there. Through regular maintenance performed by the manufacturer's team, Hongyuan Group ensures the long-term reliability of its equipment—providing peace of mind to its partners.

Compared to competitors, the iX6 et iP6 models reduce cutting buffer by 1-2 mm thanks to the ‘cutting while the conveyor advances’ feature… The efficiency of cutting while the conveyor advances boosts overall productivity by 5%.

Jianxin Li, General Manager, Hongyuan Group

Discover the solution

Vector Automotive iP

Hongyuan Group and Lectra: A successful collaboration

Hongyuan Group is committed to not just existing quality standards but also focusing on continuous growth. In collaboration with industry leaders like Lectra, they are striving to advance intelligent manufacturing practices. This strategy aims to drive ongoing innovation while solidifying their market position.

The history of Hongyuan Group is one of commitment to excellence, innovation, and collaboration. By integrating advanced technologies and focusing on continuous improvement, Hongyuan Group is ready to face future challenges while providing exceptional quality products to its customers.

Latest resources