From chalk to cloud with Versalis Digital Marking

Transform leather cutting with Versalis Digital Marking. Replace chalk marking with a data-driven process that delivers precision, transparency, and continuous improvement.

A data-first approach for leather

Leather remains a hallmark of luxury in the automotive industry, especially in premium and electric vehicles. But as OEMs demand greater efficiency, cost control, and supply chain transparency, traditional leather cutting methods are no longer sufficient.

Manual chalk marking is slow, inconsistent, and reliant on operator skill. More critically, it produces no usable data—limiting visibility, traceability, and continuous improvement.

Lectra’s Versalis Automotive Digital Marking solution replaces manual marking with a fully digitized process. The result: consistent quality, faster operations, improved yield, and smarter decisions.

Precision and performance at every stage

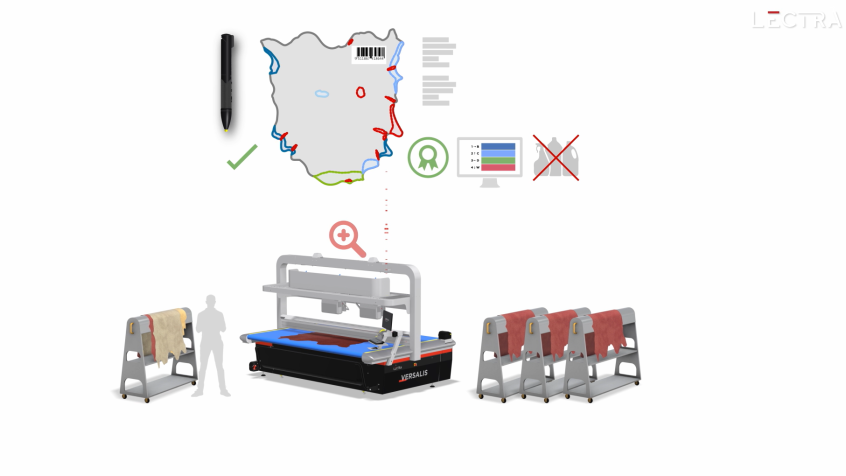

Versalis Automotive Digital Marking captures data at every stage of the leather cutting process, turning each step into a source of insight and efficiency.

Marking phase

The system begins capturing valuable data from the moment hides arrive. Digital scanning and grading replace chalk marking, giving suppliersinstant visibility into hide quality. After the operator has completed defect identification, the system automatically calculates the grading result, logs all hide data in the LeatherReporting database, and generates a barcode label for marking traceability.Stocking phase

Scanning each hide generates a digital twin, complete with usable surface area calculations and grading data. This enables better inventory visibility and digital sorting by quality. Hides that fall short of required standards can be filtered out early, while leather simulation software optimizes nesting before cutting begins.- Cutting phase

Before cutting, the hide is re-scanned on the Versalis Automotive leather cutting solution. Specialized software automatically repositions the defect map, initially generated during the marking phase, to match the current state of the hide. This compensates for natural shape changes due to humidity or handling, ensuring precise alignment with digital markings.

Strategic value of hide data

The data collected throughout the leather cutting process with Versalis Automotive Digital Marking opens up new strategic possibilities for suppliers.

Supplier oversight becomes more transparent and data driven. By digitizing and grading hides upon arrival, companies can compare the quality received against what was ordered and paid for. This level of visibility strengthens quality audits, supports more informed negotiations, and helps reduce discrepancies with vendors.

Increased nesting efficiencyis achieved through the combination of precise digital marking and automatic hide repositioning. Operators then have more time to optimize nesting strategies, resulting in better material utilization and reduced waste.

Workorder optimization becomes significantly more efficient with Versalis Automotive Digital Marking. Operators can select hides based on part type and required quality, ensuring that premium hides are reserved for high-value parts. This targeted approach not only improves material usage but also enhances consistency of finished products and customer satisfaction.

Operator performance improvement is supported by continuous data collection throughout the process. Objective, data-based metrics such as speed and marking quality enable performance standardization, identification of training needs, and successful continuous improvement initiatives.

Tangible improvements

Versalis Digital Marking delivers clear, quantifiable results that help suppliers boost performance, reduce waste, and meet OEM expectations with confidence.

- Reduced Rejections: Eliminates chalk stains and misclassified defects.

- Improved Traceability: Full integration with ERP/MES and real-time dashboards.

- Sustainability Gains: No chemical cleaning required; less waste generated.

Smarter leather cutting

By digitizing every stage of the leather cutting process, the Versalis Automotive system enables suppliers to take full ownership of the leather value chain, allowing them to cut in-house, inspect hides themselves, and ensure consistent quality from start to finish. As OEMs raise expectations, Versalis Automotive helps suppliers stay ahead with greater efficiency, transparency, and sustainability.

Our solution

Versalis Automotive

Related content