Changchun Faway Adient has adopted Vector Automotive iP to meet the production excellence

The main challenge for Faway Adient is meeting customer demands in terms of production and quality. That is why they turned to Vector Automotive iP.

Faway Adient opted for Lectra's latest Vector Automotive iP9 cutting solution

As a leading automobile components supplier, Changchun Faway Adient Automotive Systems Co., Ltd. (henceforth referred to as Faway Adient) has consistently focused on the development and implementation of innovative technologies. It is an early adopter of digital integration in manufacturing.

Faced with new technological developments in the automotive market and evolving customer needs, Faway Adient recently introduced Lectra’s latest digital cutting solution, VectorAutomotive iP9, to further increase production capacity and reduce costs.

With the ongoing economic downturn and increased competition in the automotive market, companies are centering on innovation and technological quality in order to gain a stronger foothold, as upstream suppliers now have to meet requirements that are more stringent.

Taking its brand Hongqi as an example, since implementing its new brand strategy in 2018, the company has made pursuit of excellence its major objective and, as a result, is achieving growth despite the market downturn. According to reports, the new Hongqi brand has established world-class quality standards and extremely stringent process control requirements. They have been working exclusively with the world's leading suppliers that are obliged to meet extremely rigorous inspection standards and requirements to ensure high product quality and production capacity.

As a supplier of automotive seats for Hongqi, Faway Adient responded quickly to new customer needs, making adjustments and continuously optimizing its production, R&D, and supply chain management systems to meet rising expectations. However, some existing production equipment and supply systems were no longer able to meet its strategic development needs. For example, its fabric cutting equipment had been falling short in terms of production capacity and cost-savings.

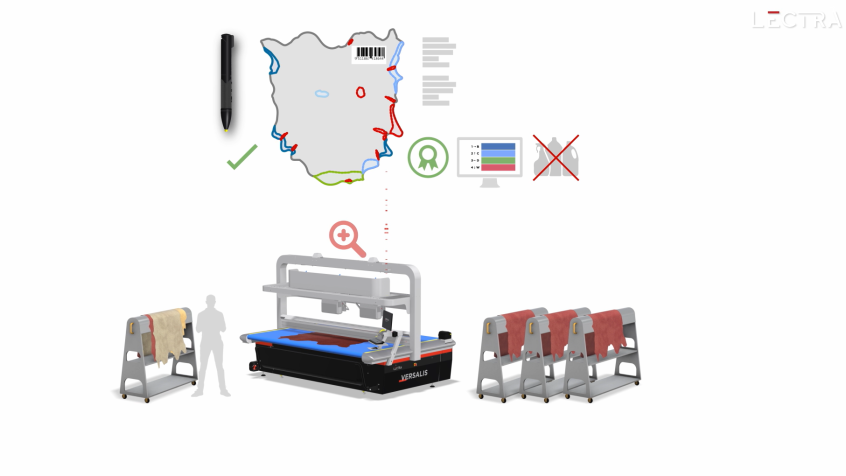

To counter this, Faway Adient opted for Lectra's latest Vector Automotive iP9 cutting solution after multiple rounds of testing and validation. The new system not only meets its project requirements but also offers Dashboard services that enable real-time monitoring of the cutting room with cutting efficiency and other key production indicators, providing data for continuous improvement to the management.

Vector Automotive IP

About Faway Adient

Changchun Faway Adient Automotive Systems Co., Ltd. (Faway Adient in short) is a Sino-foreign joint venture established on August 22, 2001, jointly invested by Changchun Faway Automobile Components Co., Ltd. and Adient PLC in the United States and located in Changchun City in Jilin Province, known as the cradle of China's automotive industry. Its registered address is 4736, Dongnanhu Avenue, Changchun Economic and Technological Development Zone, its registered capital amounts to USD 59.6 million, and it covers an area of 530 thousand square meters. Faway Adient currently has more than 7,966 employees, with 8 functional departments, 3 factories, 1 subsidiary, 5 branches, and 3 joint ventures. Its business scope includes the development, design, manufacture, sales, and after-sales service of automotive seats, instrument panels, consoles, door panels, headliners, vehicle electronics, and trim products.

For more information, please visit http://www.faway.com.

Latest resources