Embracing data intelligence to win in complex and challenging markets

The fashion industry is facing a dramatic change in consumer demand and its top decision-makers, in order to maximize shareholder value and achieve key strategic goals, are seeking to strike the perfect balance between process transformation and business continuity.

Data intelligence: an empowerment for the transformations of the economic landscape

Data intelligence empowers fashion executives to gather the relevant information needed to make informed decisions and understand what they must do to succeed in a changing marketplace. CEOs are able to build for their companies, resilience against market volatility and capitalize on new opportunities without negatively influencing their existing revenue streams. Winning new customers and selling more to existing customers becomes easier when companies are empowered with the right data.

Fashion businesses that leverage data exploitation are able to make efficient use of capital, labor and material resources to increase their speed to market, lower production costs, and function effectively with minimum waste. The benefit is gaining transparency throughout their value chain and the operational agility to quickly read and respond to shifting consumer trends. Companies learn how to develop and deliver faster the innovative products, services and superior customer experiences that today’s consumers want.

In essence, adapting manufacturing processes to take advantage of data means smarter risk management and stronger resilience to the randomness, shocks and uncertainty of today’s businesses cycle. Executives choosing this model gain capabilities unique to high-performance organizations—growing market share, reducing costs, and expansion to new markets— and find it easier to attain operational excellence and value creation.

Three reasons why manufacturing success begins with data

1. Maximize asset utilization

Executives enabled with predictive maintenance and real-time data tracking of machine performance are not only able to find the root cause of machine failure and eliminate it ahead of time—identifying equipment issues before a breakdown takes place—but also choose an accounting model, change a maintenance strategy, and become more profitable.

A predictive maintenance program, according to a recent report by the US Department of Energy, a can deliver a tenfold increase in ROI, 25%-30% reduction in maintenance costs, 70%-75% decrease of breakdowns and 35%-45% reduction in downtime.

2. Strengthen stakeholder collaboration

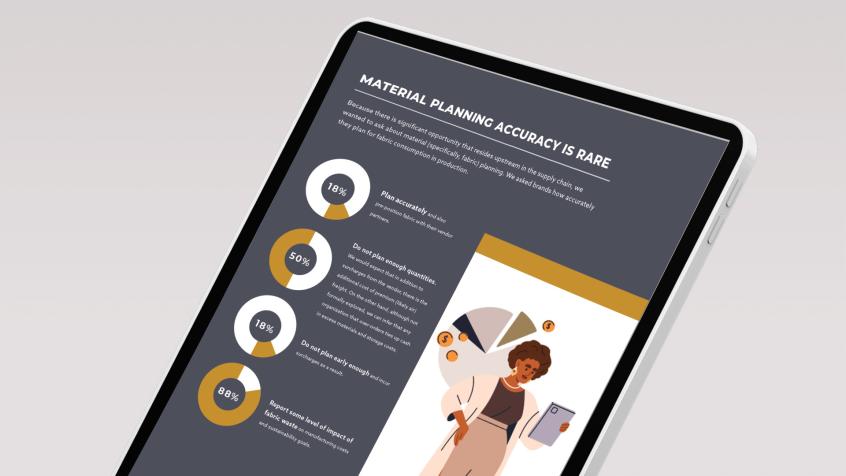

Total visibility of production workflows and advanced monitoring of material usage enable manufacturers to connect and exchange operational data between the people, processes and technologies driving their cutting preparation and execution. The result is deeper collaboration and information sharing to make better, time sensitive, decisions that influence the bottom line.

Managers benefit from data traceability by gaining complete visibility of material requirements, which represents up to 70% of the cost of manufacturing a garment, to make accurate cost saving decisions. Operation teams benefit by gaining the ability to consult shared product data at any moment of the workflow to incorporate up-to-date data into their approval and reporting processes.

3. Accelerate product innovation

Access to real-time user data enable fashion executives to anticipate trends and assess where products or services are in demand. Manufacturers gain insight valuable to product development based on consumer and market situation data. The power to learn what customers want combined with the operational flexibility to make iterative improvements on their offer to specific regions and demographics enable manufacturers to meet consumer demand for greater diversity of product choice and deliver new products to market faster.

Companies taking advantage of a data-driven product development process—customer co-creation/open innovation, concurrent engineering, and rapid experimentation and simulation—are able to reduce time to market by 20 – 50% claims a recent McKinsey report on the benefits of adopting Industry 4.0 practices in the manufacturing process.

Achieving success in today’s fashion market requires the skillful ability to navigate industry changes—like new markets, new technologies and shifting consumer needs—and take the right action in each situation to exceed customer expectations. The unparalleled amounts of transparency and agility, gained from data intelligence, enable fashion executives to improve organizational resilience and profit from new insights to make smarter decisions faster.

Related content