Make zero-buffer multi-ply cutting a reality

Maximize automotive upholstery savings with Lectra’s VectorAutomotive iP series

VectorAutomotive iP6 and iP9

The industry standard for multi-ply cutting

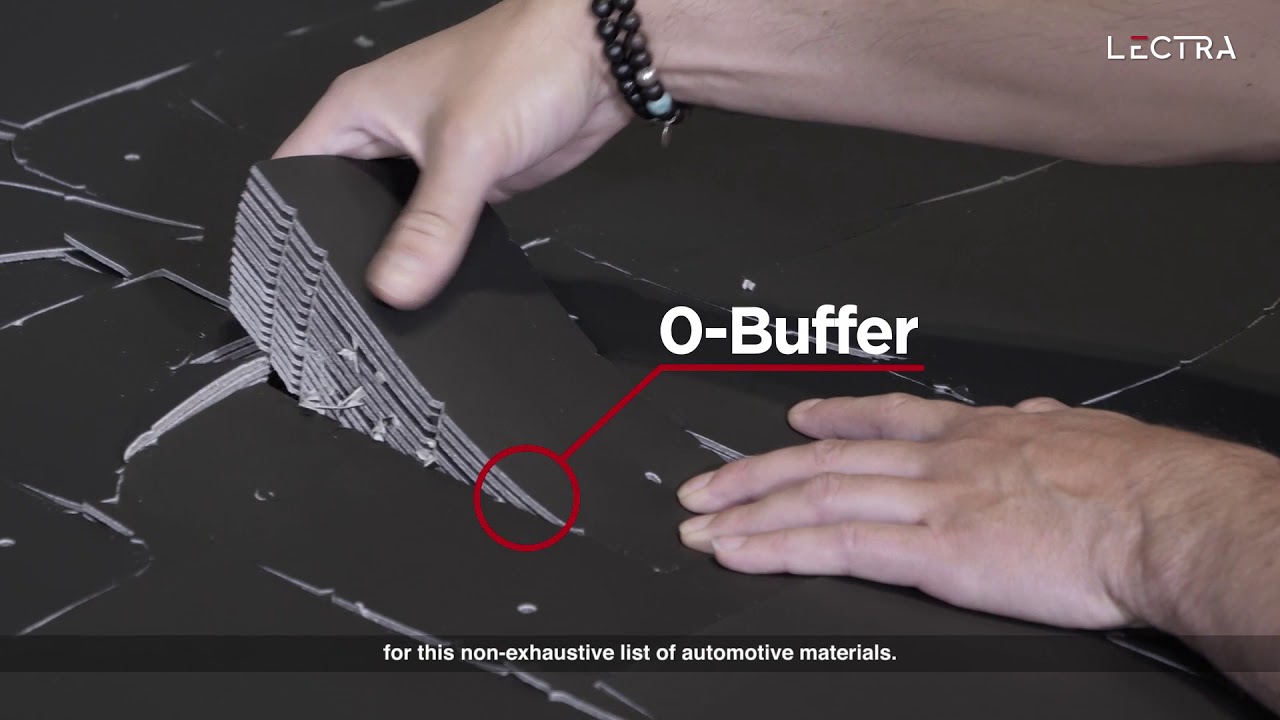

Lectra’s VectorAutomotive iP series is specially designed to achieve zero- and near-zero-buffer cutting at the highest productivity level on the market. VectorAutomotive iP6 and iP9 are built on the unmatched machine availability of the previous generation of fabric cutter, Vector iX9. Thanks to major advances in hardware, software and consumables, VectorAutomotive iP6 and iP9 set the industry standard in terms of cutting accuracy, reliability, machine availability and material efficiency for a wide range of automotive materials and cut parts.

Three major advances

Maximize multi-ply cutting productivity and cut part quality

- Adjust cutting parameters in real time

New image sensor technology works in tandem with a dynamic conveyor system to detect stress and instantaneously adjust cutting parameters. - Precision-cut a wide range of materials

Built-in blade management system guarantees high-precision cutting with the greatest degree of accuracy possible. - Achieve high-ply cutting on thicknesses up to 9cm

Specially designed sintered steel blades can cut up to 9cm of synthetic and foam-backed materials without breakage.

Vector iP series

Designed to meet today’s cost challenges

For every 1mm reduction in cutting buffer, automotive suppliers can achieve a 1% gain in material and the equivalent in roll goods, resulting in savings that amount to several hundred thousand dollars annually compared to other fabric cutting solutions available on the market.

More on our fabric-cutting range

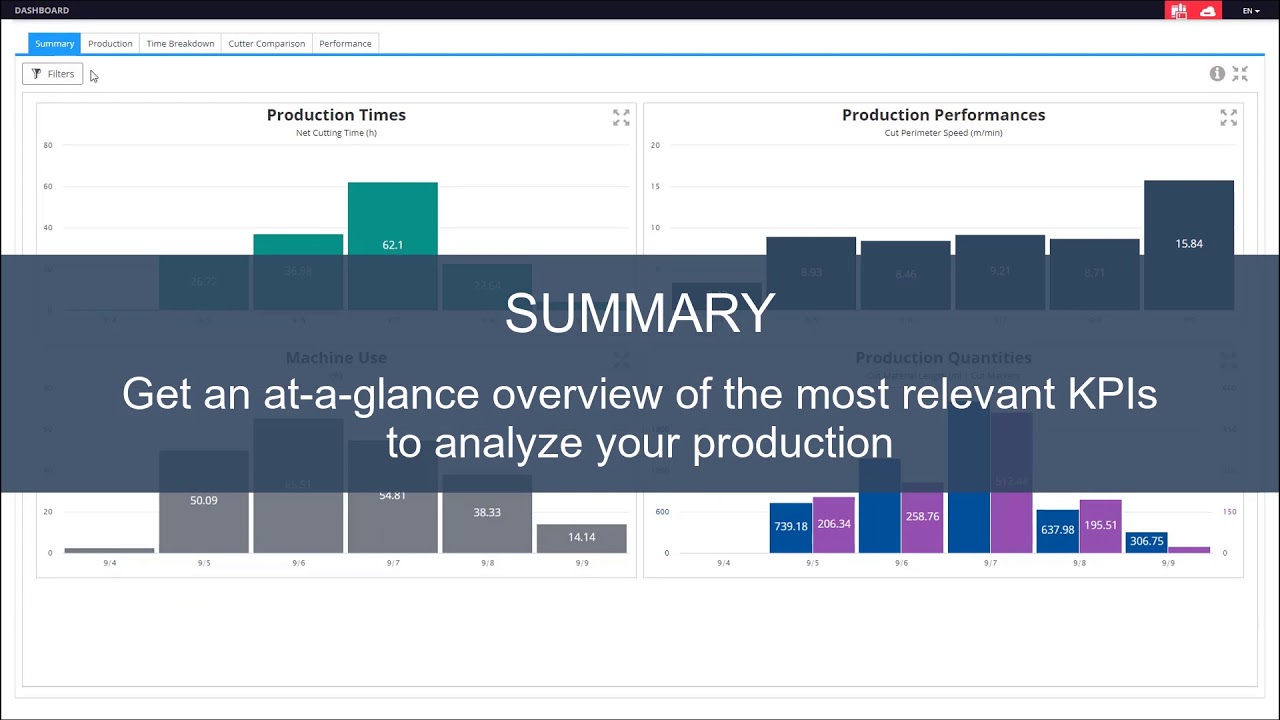

Vector Dashboard

Vector Dashboard is a cloud-based application that allows you to view key performance indicators day to day, to monitor the production performance of each installed Vector fabric cutter. It places centralized data at your fingertips, with an at-a-glance view of KPIs and quick identification of areas for improvement.

Vector automotive range

Related content