Building a resilient future with Vector Automotive iP and Algopex

Achieve new efficiencies and stay competitive—see how Vector Automotive iP and Algopex are reshaping automotive interior manufacturing.

Modernizing for market resilience

The automotive industry faced a turbulent 2024 and the outlook for 2025 remains uncertain as manufacturers deal with persistent challenges and emerging trends.

In the rapidly evolving landscape of automotive interior manufacturing, long-term resilience depends on more than just innovative designs and high-quality materials—updating cutting room technology is essential.

To ensure sustained competitiveness and adaptability, it is crucial for automotive interior manufacturers to invest in modern cutting solutions that enhance performance, streamline operations, and future-proof their production capabilities amid an ever-changing market environment.

Limitations of outdated cutting equipment

Older cutting solutions often struggle to keep pace with the current demands of automotive interior manufacturing. These aging solutions may lack the capabilities required for today’s precision and speed needs, impacting material usage and throughput.

With age, they become more prone to malfunctions, leading to higher repair costs and unexpected downtime.

As a result, manufacturers relying on outdated solutions face greater operational challenges and inefficiencies.

Upgrading is no longer a luxury—it’s a strategic move to overcome these operational challenges and unlock new efficiencies.

Vector Automotive iP: a next-gen fabric cutter

Vector Automotive iP, the most recent state-of-the-art addition to the Vector range, blends advanced hardware, intelligent software, and robust engineering to deliver unparalleled precision and efficiency.

Reduced ownership costs, faster ROI

Durable components and long-lasting consumables reduces Vector Automotive iP’s maintenance requirements by half compared to previous models, allowing your team to focus on production rather than upkeep.

The combination of extended part lifespans and an optimized maintenance schedule also translates to lower expenses for consumables and maintenance kits.

This efficiency not only reduces operational costs but also delivers a return on investment within an average of 12 to 24 months.

Real-time monitoring, maximum uptime

Equipped with built-in sensors, Vector Automotive iP can anticipate potential production issues, thereby enhancing equipment productivity.

These sensors facilitate real-time monitoring, enabling Lectra experts to swiftly alert manufacturers to any equipment anomalies, ensuring optimal performance is maintained.

This proactive approach minimizes downtime and reduces repair costs, allowing production to run smoothly. Additionally, regular preventive maintenance not only guarantees consistent cutting quality but also helps lower waste and operational expenses.

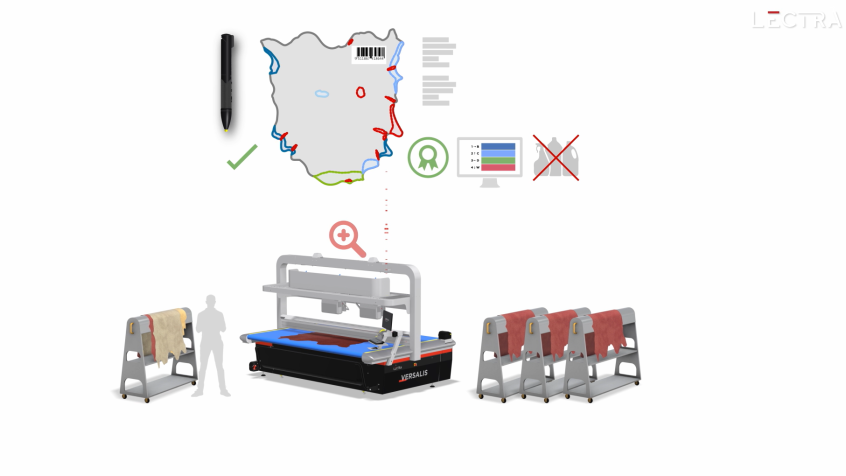

Connected cutting room

Algopex: Data-driven cutting room optimization

Data plays a pivotal role in increasing efficiency, reducing costs and unlocking productivity and profitability for automotive interior manufacturers. Algopex, Lectra’s cloud-based data analytics and visualization tool, provides real-time insight into cutting room operations. By harnessing the power of manufacturing data, suppliers can improve their production times, productivity and quality.

Actionable insights from cutting data

Real-time monitoring of cutting lines, combined with automated alerts, provides customers with an unparalleled overview of production across all their sites.

These alerts, conveniently displayed on the shop floor and sent directly to mobile devices, empower teams to make timely interventions, reducing downtime and keeping operations running smoothly.

Managers can effortlessly access real-time data and analytics from anywhere in the world, enabling them to immediately identify line performance issues, bottlenecks, and potential disruptions. This ability to respond proactively not only enhances operational efficiency but also supports consistent production quality, ultimately leading to increased customer satisfaction and improved profitability.

In addition, visualizing cutting room performance (by cutting line and operator, for example) empowers employees to see the direct impact of their efforts. When teams can track improvements in efficiency and quality, they become more motivated and engaged in meeting performance goals.

Keep pace with industry performance benchmarks and track improvement

Algopex plays a crucial role in helping automotive manufacturers maintain a competitive edge. By integrating advanced data analytics and reporting capabilities, Algopex empowers manufacturers to benchmark their cutting room performance against established industry standards.

This valuable benchmarking provides clear insights into performance metrics, enabling manufacturers to assess their position relative to competitors and pinpoint specific areas for improvement.

Algopex further enhances decision-making by recommending corrective measures. Managers can uncover potential savings and optimize operations by answering contextualized questions such as:

- Are the same markers cut with different parameters?

- Is the number of interruptions linked to offloading abnormal?

- Is the positioning time too long?

Stay on target with personalized support

Premium-experience customer service provides support and individualized follow-up to ensure that customers reach their goals.

With a dedicated support team available, companies benefit from a single point to contact to ensure successful onboarding and efficient use of their Lectra solution.

Performance data in real time

Better together: A connected cutting room

While each solution offers significant benefits on its own, the combination of Vector Automotive iP and Algopex is truly transformative.

The precision and efficiency of Vector Automotive iP is amplified by the real-time insights and analytics provided by Algopex.

By combining precision cutting with intelligent data analytics, automotive interior suppliers can unlock unprecedented operational efficiency and elevate customer satisfaction.

This integrated approach transforms the cutting room into a strategic asset that bolsters the long-term resilience of automotive suppliers.

Latest Resources