Why cutting order planning is the key to achieving cutting room productivity and profitability

In this article, we’ll explore how cutting order planning impacts operational efficiency, reveal the hidden costs of poor planning, and show how digital solutions such as Valia Fashion deliver measurable improvements in performance and profitability.

Unlocking cutting room efficiency through smarter planning

In the fashion industry, the cutting room is often perceived as a technical space where fabric is processed before assembly. In reality, it is also one of the most strategic levers for profitability. Every meter of fabric saved, every minute of machine time optimized, and every order executed on time contributes directly to the bottom line.

At the heart of this performance lies a process often underestimated: cutting order planning. When executed effectively, cutting order planning transforms the cutting room into a powerful driver of productivity, cost control, and agility.

How cutting order planning drives performance

A robust cutting order planning process enables manufacturers to:

1. Anticipate and allocate resources efficiently

By consolidating orders and estimating fabric requirement with precision, planners align cutting schedules with material availability and cutting equipements and spreaders capacity. This minimizes idle time and ensures that machines run at optimal throughput.

2. Reduce human error and manual tasks

Manual transmission of order and production data causes errors, delays and fabric waste. Automated rules and digital workflows replace repetitive tasks and reduce the risk of costly mistakes. Teams follow a standardised, data-driven process instead of relying on tribal knowledge or last-minute decisions.

3. Respond rapidly to changing priorities

A flexible cutting order planning system allows planners to reconfigure production without disrupting the entire workflow—an essential capability today’s fast-moving market.

4. Enhance collaboration across teams

When product, material, and order data are centralized, planning and cutting work seamlessly together. Everyone operates from the same source of truth, reducing delays and miscommunication.

In short, cutting order planning is not only about planning—it is about orchestrating the entire cutting room ecosystem.

Case study: from reactive to predictive

Before Valia Fashion, our planning was reactive. We spent hours adjusting orders manually and still faced delays. Now, with automated rules and real-time dashboards, we anticipate issues before they happen. Our fabric savings alone paid for the system in less than a year.

Operations Director, European garment manufacturer

This testimony illustrates a familiar journey: moving from firefighting and inefficiency to control, agility, and continuous improvement. The enabler is clear: a structured, digital approach to cutting order planning.

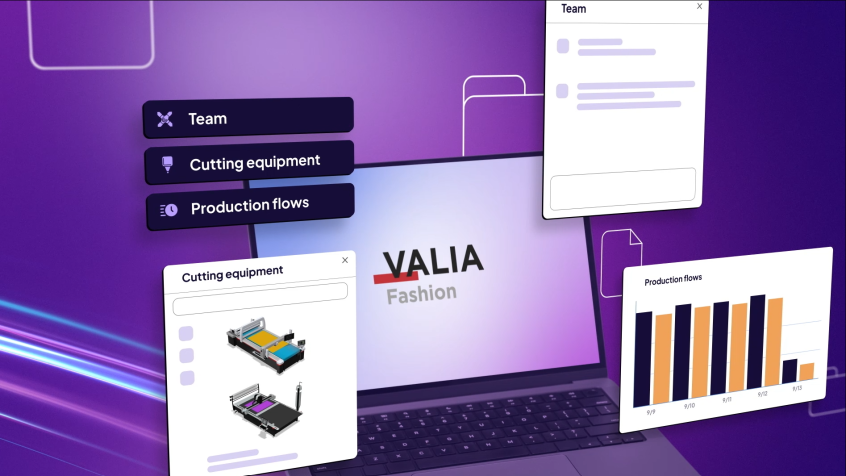

Why Valia Fashion makes the difference

Valia Fashion is a cloud-based solution that integrates:

- Product and material data

- Fabric estimation

- Order execution and automation

- Performance tracking

Its cloud-based architecture ensures scalability, security, and real-time collaboration across teams and sites. With Valia Fashion, manufacturers replace fragmented tools with a unified, intelligent workflow that supports both operational excellence and strategic decision-making.

As a centralized data system, Valia Fashion can reduce manual entry errors by up to 80% and can accelerate order preparation by up to 75%"

Operations Director, European garment manufacturer

From necessity to strategy

In today’s competitive fashion market, where margins are tight and customer expectations high, cutting order planning is no longer a back-office task. It’s a strategic capability that influences cost control, delivery performance and sustainability.

Valia Fashion

Frequently Asked Questions (FAQ)

What is cutting order planning in fashion?

It’s the process of transforming product orders into optimized cutting instructions, balancing fabric usage, production constraints, and delivery timelines.

How does cutting order planning impact profitability?

By reducing waste, improving machine utilization, and accelerating order execution, cutting order planning directly lowers costs and increases margins.

What’s the best software for cutting order planning in fashion?

Integrated platforms such as Valia Fashion provide estimation, automation, and performance tracking in one system — making them ideal for modern cutting rooms.

Related Content