Deadlines, costs, and staff shortages: The reality of contract furniture manufacturing

How to shift between high and low volume production with labor shortages

Why is scaling production so challenging in contract manufacturing?

Contract furniture manufacturers play a key role in creating safe and functional spaces in places like hotels, offices, restaurants, and cafés. However, in today’s business environment, scaling up production is becoming more difficult due to labor shortages, limited access to machinery, and unclear cost structures.

1. Limited workforce for big contract furniture projects

1. Limited workforce for big contract furniture projects

Furniture manufacturing remains highly labor-intensive, and many factories face challenges in hiring skilled operators. However, scaling up for large-volume projects demands additional production lines and shifts.

2. Adapting to low-volume, high-customization production

2. Adapting to low-volume, high-customization production

The contract furniture market is shifting from mass production to customized, small-batch runs. This complexity slows down planning and production workflows.

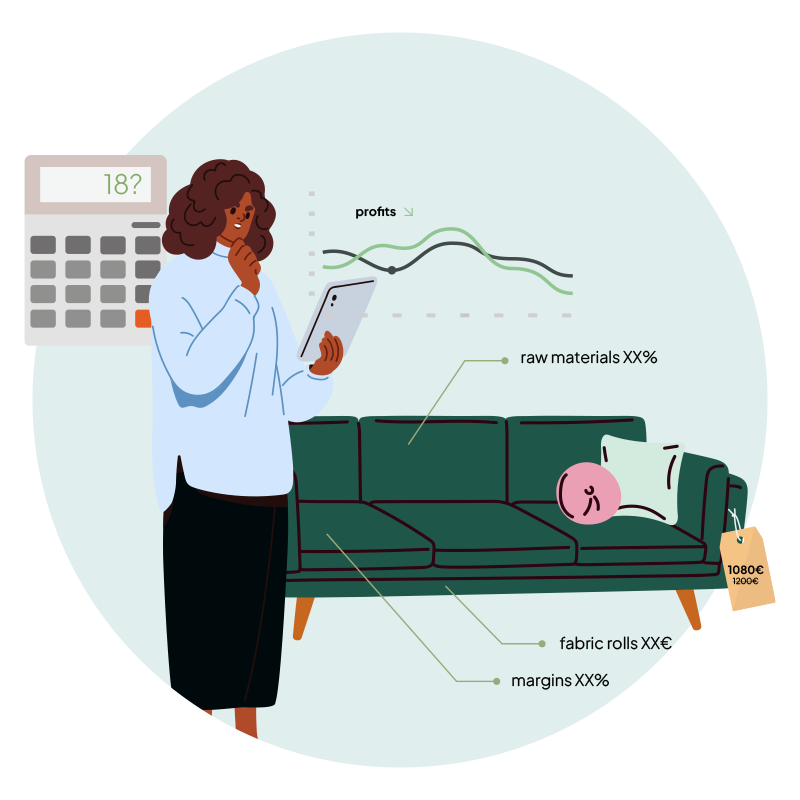

3. Limited cost-tracking is driving profits down

3. Limited cost-tracking is driving profits down

Without clear visibility into labor and material costs, it becomes difficult to accurately track expenses and price projects effectively. This can lead to hidden margin erosion.

Download the infographic

Read our infographic now

Related content