Protective wear leader Workwear Outfitters revitalizes and automates its cutting room with Lectra’s technology

Leading Nashville-based protective workwear supplier implements Lectra’s Industry 4.0 cutting equipment and cloud nesting solution to meet rising consumer demand.

Workwear Outfitters, a leading protective workwear supplier in Nashville, Tennessee

Workwear Outfitters is a company that was founded over 100 years ago in Nashville, Tennessee. With a solid reputation of catering to top-tier customers such as Image Authority® and Chef Designs®, they champion and empower workers in industries including automotive, manufacturing, oil and gas, utilities, government, food services, telecommunications, hospitality and more.

The growing potential of the global protective workwear market

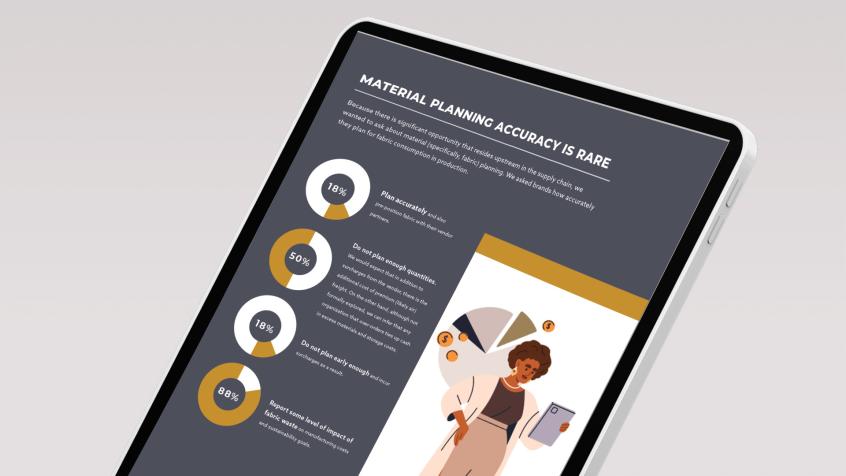

With a projected market size worth $45.74 billion by 2028, according to The Insight Partners, the workwear industry is showing no signs of slowing down. It was time for Workwear Outfitters to adjust its manufacturing strategy to keep up with demand, which entails revamping their cutting room with automated fabric-cutting equipment and nesting software.

Automating cutting and nesting with Lectra’s next-generation technology

Over the past year, Workwear Outfitters started using the latest Lectra solutions in all their manufacturing facilities, including high-performance, Industry 4.0 multi-ply cutting equipment, as well as fully connected marker-making software such as Gerber AccuMark and Flex Offer by Lectra. They also replaced four of their older spreading solutions with Lectra 750S, and are planning to purchase eight more in the future.

Increased material savings and profitability

With the powerful combination of Lectra’s technology and customer support, they can streamline their manufacturing to stay ahead of demand, increase material savings and profitability. The solutions have saved them an extraordinary amount of material and costs, especially in terms of fabric procurement. Thanks to accurate fabric consumption estimates, they are now able to procure the right amount of fabric without causing any surplus.

Download the complete testimonial

Testimony

Fernando Goya

Related content