When it comes to choosing a location for apparel manufacturing, which criteria matter for fashion’s decision-makers?

While they may initially go for China - other countries in Asia also offer attractive competitive advantages.

China ticks all boxes but two: labor costs and availability

China remains first choice for textile and apparel sourcing thanks to: its efficient supply chains; sufficient domestic supplies of raw materials; and the government’s efforts to shift production to higher tech modes.

However, it lacks two competitive advantages: the availability of workers and cheap labor costs. Skilled workers are hard to recruit and retain, while the minimum wage is twice as high as in Vietnam, and keeps on rising.

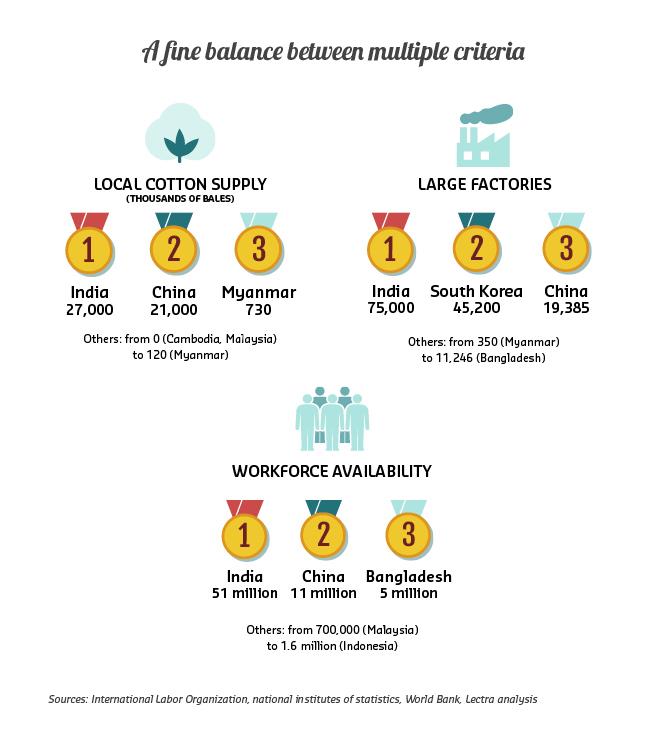

Competitors in the region leverage different sets of assets

Each country in Asia offers a different set of pros and cons for apparel manufacturing. In India, inefficient supply chains and poor infrastructures contrast with the huge potential provided by low labor costs and plenty of raw material supplies.

Despite lacking technological advancement and proper working environments, Bangladesh is racing ahead in ready-made garment exports. As for Cambodia and Myanmar, low labor costs make up for the high dependence on raw material imports, mainly from China.