When it comes to transparency and traceability, many fashion companies are still struggling. According to Fashion Revolutions 2021 Transparency Index, only 47% of brands are disclosing their first-tier manufacturers and just 11% publish selected raw materials suppliers. Some of the biggest challenges regarding transparency and traceability include difficulty collecting and validating data and limited visibility with sub-suppliers.

In order for fashion brands to improve traceability and transparency, they need to rethink their current supply chain operations.

Addressing problems with visibility

Over the last year, many fashion brands have invested in technology, such as eCommerce and other virtual experiences, in order to stay connected with their customers throughout the pandemic. However, with as much investment as there is on the front end, brands are still lacking on the backend, which is a crucial in improving visibility into a product's materials, origins and current whereabouts.

This real-time visibility is vital in fashion, particularly as more shoppers demand answers on where their garments come from. Unfortunately, many brands are still using spreadsheets, documents and other manual processes to track data, which is not efficient or effective in generating the insights consumers often seek.

The good news is more brands are realizing the benefits of digital integration, so we will likely see back-end technology adoption increase, thus granting them access to more data.

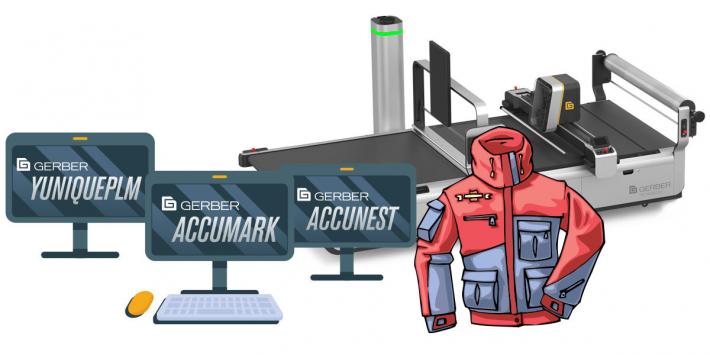

With technologies addressing PLM, PIM, DAM, 2D/3D CAD, and automated nesting, fashion brands will be able to fully connect their supply chain, allowing them to seamlessly pass data from design to final product. This integration will not only empower brands to deliver their products to market faster, but it will also allow them to maintain data throughout, ensuring accuracy at every step.

Enhancing supplier communication

The other key challenge to overcome for true transparency and traceability is getting better information on suppliers. According to the 2021 Transparency Index, only 4% of brands disclose a summary of findings at the raw material level, which is a problem when 73% of consumers believe fashion brands should publish the suppliers they use to source fabric and raw materials.

Many fashion brands struggle to get information from their suppliers due to the lack of visibility and accurate information. In order to combat these problems, brands must rely on technology to enhance communication with their suppliers. This not only means integrating new technology into the supply chain, it also means working with suppliers who are already utilizing technology, making it easier to get the data you need.

A partner for the future

Lectra, offers a complete end-to-end solution for fashion, which includes all the latest technology from PLM to CAD to automated, digital cutting. By partnering with Gerber, many brands have already been able to improve transparency and traceability. For example, by leveraging Gerber’s PLM solution, YuniquePLM®, Houdini Sportswear was able to improve their efficiency and become more transparent. With YuniquePLM, Houdini is now able to manage a full scope of activities across the product lifecycle, allowing them to make progress towards their goal of having 100% of their products be made from recycled or biodegradable fibers and be recyclable or biodegradable at end-of-life.

“We chose YuniquePLM as it can facilitate all of Houdini’s specific demands – from financials to finished product,” said Eva Karlsson, CEO of the outdoor brand. “As we design every product with the intention of it making a difference for the end user and for the world, transparency and traceability are essential in our way of doing business. Up until we leveraged YuniquePLM, we had worked in many different ways, using documents and lists.”

Gerber’s integrated solution connects the entire supply chain from design through production, allowing fashion brands to maintain visibility throughout the entire product lifecycle. In addition to improving transparency and traceability, Gerber’s solution also helps accelerate time to market, reduce waste and improve working conditions.

Technology is a must

When it comes to transparency and traceability, fashion brands need to take responsibility. In order to gain consumer trust and provide them with accurate information, they need to integrate technology into the supply chain. Technology will not only allow them to maintain data throughout the design and production processes, but it will also improve communication with suppliers, which is one of the biggest challenges when it comes to transparency and traceability.

The bottom line? Technology is no longer an accessory but a requirement to meet consumer demands.

Posted on 12 Jul 2021