The company was facing two main challenges: they needed to adopt more eco-friendly operating practices to reduce their carbon footprint, and also manage two manufacturing plants in different countries, one in Morocco and Tunisia. They wanted to find a way to monitor the performance of each plant, identify areas for improvement, and implement change remotely. Thanks to Algopex™, Lectra’s value-added services package, they were able to increase their raw material savings by 3.5% and their production capacity by 2% within six months via real-time KPI-monitoring, -tracking and -benchmarking.

How automotive seating manufacturer Tesca increased its cutting capacity with Algopex™

Watch the recording of our annual digital event to find out how this renowned company Tesca achieved operational excellence with the help of Lectra’s new value-added, data-driven services package for continuous improvement!

From early adopter to advocate of Algopex™

Seeing is believing

Get to know Algopex™ through the eyes of Tesca. Watch the recording of our product launch that took place on June 23, 2022. Our Global Corporate Business Consultant, Germano Nobili is going to interview Tesca’s Deputy Director, Renaud Cellier and Quality Assurance Director, Alexandra Oliviera to hear firsthand how Algopex™ has been improving their everyday working lives.

Watch the video

Tesca’s story

Tesca is a French-based family-run company that leverages its textile savoir-faire to serve the automotive industry, expanding its business from creating fabrics to manufacturing automotive seating. Operating like a French luxury house of automotive manufacturing, the company works on each piece with care and precision, from its sampling workshops to production sites worldwide. As a partner of major automotive manufacturers, it cultivates an environment of creativity and innovation. Their customers include Audi, Bentley, Chevrolet, Citroen, Dacia, Datsun, DS Automobiles, Fiat Chrysler Automobiles, Ferrari, Ford, General Motors, Hyundai, Jaguar, Lada, Land Rover, Mahindra, Mercedes Benz, Toyota, and Volkswagen.

About our customers and experts

Germano Nobili is supporting Lectra customers in their digital transformation and Industry 4.0 implementation as a Global Corporate Business Consultant. He joined Lectra eight years ago after six years at Capgemini.

Renaud Cellier joined Tesca 30 years ago in France. He worked as a Process Engineer, Project Manager, Operations Manager before becoming the Managing Director of the company’s textile plant in France. He then evolved as Operations Director and is now managing the materials business unit as Deputy Director.

Alexandra Oliveira started her career in the electronics industry managing the process and installations team and became Quality Assurance Director, driving various projects at different OEM plants. She joined the Tesca group as Industrial Projects Leader 20 years ago, developing a specific expertise in leather and quality assurance. In May 2018, she joined the corporate industrialization team, and is currently spearheading the ‘Optimize and Dashboard’ project for the entire Tesca group.

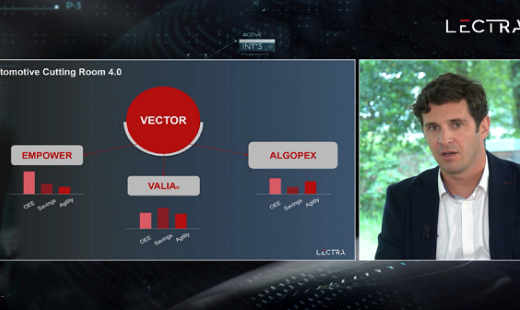

Welcome to the future: our new Automotive Cutting Room 4.0

Watch the recording of our digital event to find out how you can unlock the power of your production data with our new 4.0 cutting room capabilities!

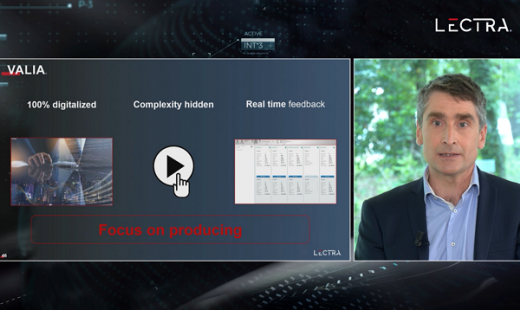

Cutting preparation and planning made easy with Valia

Watch the recording of our automotive digital event to see how Valia can help you simplify your automotive cutting planning and preparation processes by creating a fully integrated and digitalized production workflow.

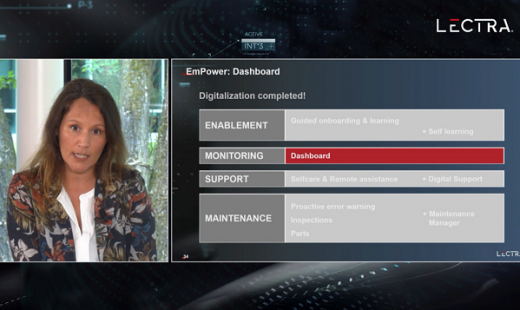

EmPowering your Vector: Using connected maintenance to achieve outstanding cutting performance

Watch the recording of our digital event to take a closer look at our automotive cutting room 4.0 components, Vector, our best-in-class zero-buffer fabric-cutting solution and EmPower, our next-generation service package.